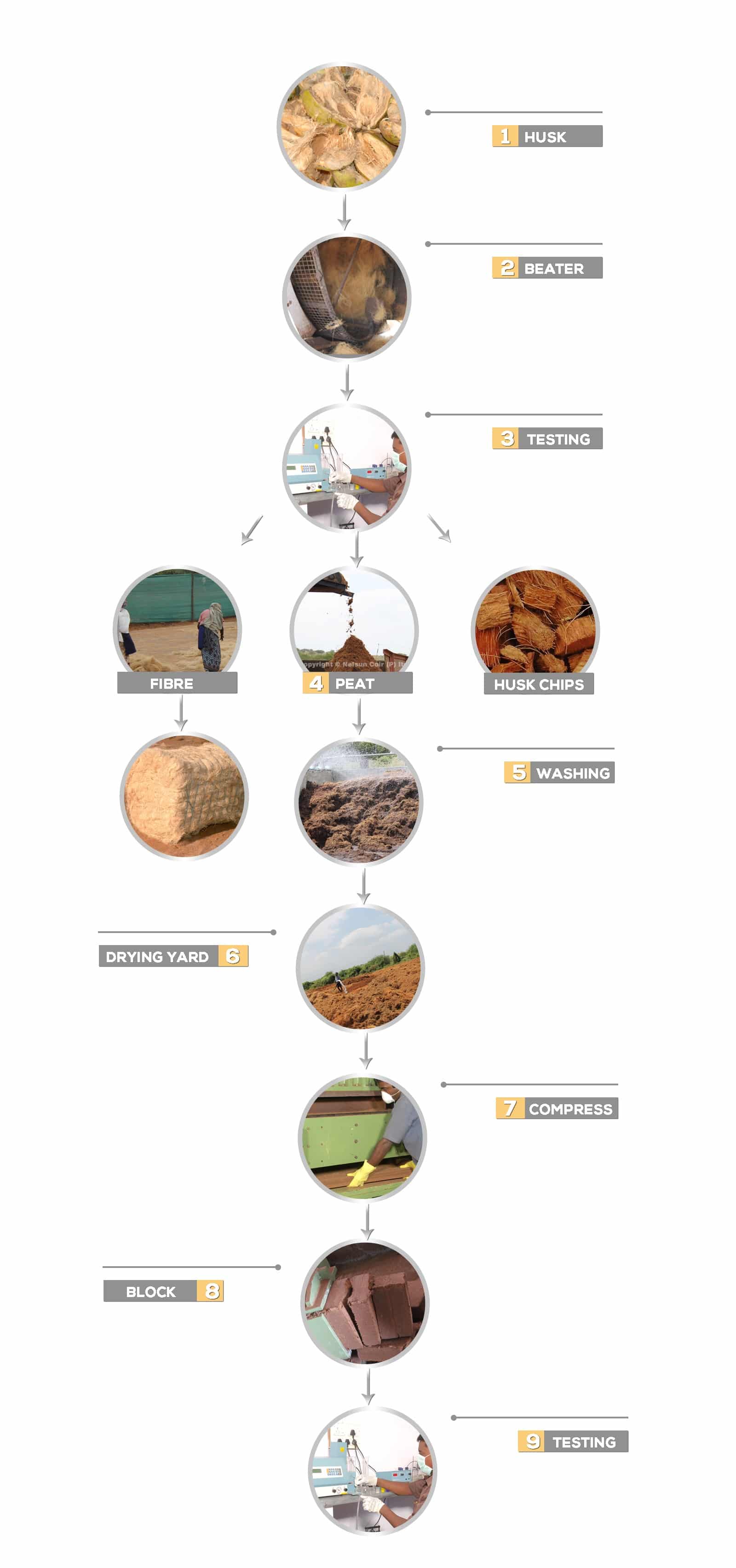

The quality of a product greatly depends on its manufacturing process; therefore, we at Nelsun Coir strive hard to follow the best manufacturing process, while checking quality at every stage, to produce the best quality products.

- The raw materials (wet pith) are sourced from nearby fiber mills or from our own fiber mill

- This is then washed and neutralised with an EC below 1,S/cm or 0.5 mS/cm and then naturally dried under the sun in our large cemented yards.

- They are then processed (cleaned, sieved to size, mixed as per recipe, adding chemicals if required), and dried again to specifications.

- In order the achieve higher loadability, the dried materials are compressed into 5kg blocks, 650 gm briquettes, or in growslabs

We always vouch for the highest quality standards for our products thus we have also appointed a quality supervisor for ensuring the quality of the materials. Moreover, we use a four stage cleaning procedure so that we can deliver the best quality products to our customers which will be free from sand, weed, pathogens, mud, stones and any other impurities.

The testing of the materials is also carried out in four stages;

- First stage, the tests are performed on the materials that are collected from the fibre mills;

- Second, the materials are tested after they are washed;

- Thirdly, tests are performed on the dried pith

- Finally, tests are done on the compressed block

The coir pith is first sieved in a sieving machine by using 1/4-1/2 inch mesh, then they are dried on large heaps of coir piths in the cemented yard and during this drying process we make sure that the dried pith does not come in contact with the ground. After drying another screening process is performed on the sieved piths before passing it to the final screening process to get rid of all the impurities. Thus, Nelsun Coir stands out as the best as we only believe in serving quality products.